The Competition Hates Our Guts! And Here's Why

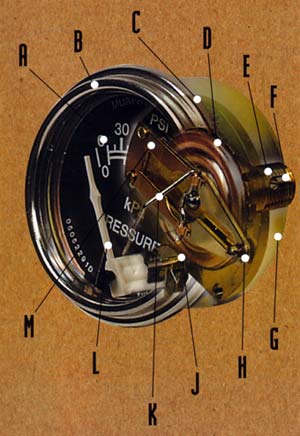

A. DIAL:

White letters on a black background, dual scale (ie. psi and kPa) standard; others

available on request.

A. DIAL:

White letters on a black background, dual scale (ie. psi and kPa) standard; others

available on request.

B. BEZEL: Polished stainless steel standard, black bezel also available.

C. MOUNTING PLATE: Machined from brass bar stock. The mounting plate performs a three fold function. It, together with the port, clamps the diaphragm in position. It provides a strong back stop for the diaphragm thereby preventing damage should the gage experience high over pressure. It also provides a stable platform which amplifies the diaphragm movement into pointer travel.

D. DIAPHRAGM: Formed from beryllium copper. The material is die formed and close control heat treated. Each pressure range is designed to operate well below its maximum capability in order to maintain reliability.

E. PORT: Machined from brass bar stock. It is accurately threaded for connection to lhe pressure line. Together with the diaphragm, it forms the pressure chamber.

F.PULSATION DAMPER: A removable restricting orifice designed to minimize shock from pressure pulsations which can cause undesirable pointer flutter.

G. CASE: Steel with zinc and iridite; mounting clamp included (except for direct mount models).

H. BRIDGE PLATE: Nickel silverplate provides corrosion resistance and it is tempered for dimensional stability.

J. POINTER POST: Riveted to the back plate and made of a corrosion resistant material.

K. CRANK ARM: Monel crankarm senses and amplifies diaphragm movement and transmits it to the pointer.

L. POINTER: Precision formed of tempered nickel silver or plastic depending on the model, with full sleeve bearing for smooth "floating" indication.

M. BEARING PLATE: Tempered beryllium copper for corrosion resistance. Provides fulcrum for crank arm. It is free to lift off the bridge plate should the pointer become restrained. It returns to original position when strain is relieved. All add to long life and accuracy.